Elite Finishing Systems

It all started with one singular paint booth system that set the tone for our entire company and our commitment to high quality.

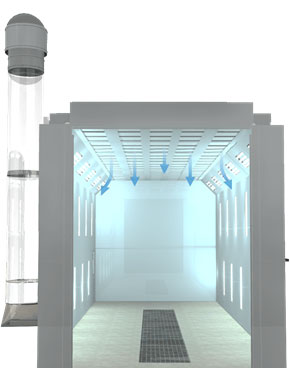

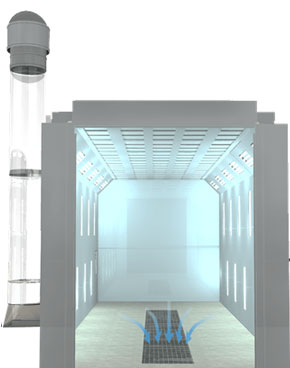

Downdraft Airflow Designs

Airflow designs are a defining element of any spray booth, so it’s one of the first things finishing operators need to consider when upgrading to a new booth.

Airflow designs are a defining element of any spray booth, so it’s one of the first things finishing operators need to consider when upgrading to a new booth.

While there are only a handful of options when selecting a type of booth, each one carries a unique set of advantages and possible drawbacks. Airflow systems impact every aspect of a booth’s operation, so companies should carefully weigh how their chosen design will affect operating costs, quality of results and workplace safety.

Recommended for:

Aerospace and Automotive + High-Quality Finishing Requirements

• Powerful Performance

• Pit Installation Requirements

• Moderate Maintenance and Upkeep

Like crossdraft airflow designs, a spray booth with downdraft airflow can accommodate a wide variety of parts and uses. However, downdraft spray booths are typically recommended for parts that require a higher quality finish. Notably, conventional downdraft airflow designs require a below-ground pit for proper operation, which creates additional installation concerns. The term downdraft refers to the direction of airflow in a downward movement from the ceiling down towards the floor of the booth.